HS Code for PCB Assembly How to Classify and Avoid Customs Issues

In international trade, PCB assemblies can get delayed, fined, or even sent back if the HS Code is wrong. Many companies waste time and money because they don’t know the correct code.

Knowing the right HS Code not only speeds up customs clearance, but also reduces taxes and risk, making your trade process smoother and safer.

In this guide, I’ll show you an easy way to identify the correct HS Code for your PCB assemblies. I’ll also share practical tips to help you avoid common customs problems.

HS Code Basics

Understanding HS Codes is very important if you want to trade PCB assemblies internationally. Let’s break it down step by step.

1. What is an HS Code and Why It Matters

HS Code stands for Harmonized System Code. It is a number that tells customs what a product is. Think of it like a label or ID card for each item you import or export.

HS Codes help customs officers know:

What kind of product it is

How much tax or duty to charge

Whether any special rules apply

Using the correct HS Code makes customs faster and avoids fines or delays.

2. Uniformity and Differences in Global Trade

HS Codes are used all over the world, and most countries follow the same basic system. That’s why it’s called the Harmonized System.

However, there can be small differences. Some countries may have extra digits, local rules, or special classifications. That means a code that works in one country might need a little adjustment in another. Checking each country’s rules before shipping is very important.

3. Common HS Codes for PCB and PCB Assembly

Not all PCBs are the same, so they have different HS Codes.

Bare PCB (the board without components) has its own code.

PCB Assembly (the board with components soldered on) usually has a different code.

The classification depends on:

How many layers the board has

Whether it’s a finished product or a component of another device

Its purpose and function in electronics

Knowing the right code for your type of PCB helps you avoid mistakes and ensures smooth customs clearance.

Common HS Codes for PCB Assembly

Different types of PCB assemblies can have different HS Codes. Using the right code is very important to avoid customs problems. Let’s look at the details.

1. Differences Between Types of PCB Assembly

Not all PCB assemblies are the same. Some are simple, with just a few components, while others are complex, with many layers and advanced features.

Simple or standard PCB assemblies usually have a basic HS Code.

High-speed or multi-layer PCB assemblies may have a different code because they are more advanced and expensive.

Specialized boards, like HDI (High-Density Interconnect) assemblies, often fall into a unique classification because of their complexity and small size.

Understanding these differences helps you pick the correct HS Code for the exact type of PCB you are shipping.

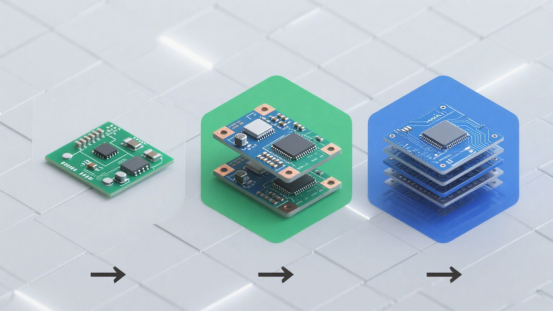

2. Differences Between Raw Materials, Semi-Finished, and Finished Products

HS Codes also depend on the product’s stage:

Raw materials: These are the copper boards, substrate materials, or other parts used to make a PCB. They usually have their own code.

Semi-finished products: These are PCB boards with some components but not fully assembled. They may need a different HS Code than the final product.

Finished products: Fully assembled PCBs that are ready to be used in devices usually have another code.

Classifying your PCB assembly based on its stage ensures customs officers know exactly what they are dealing with.

3. Common Codes for High-End PCB Assemblies

High-end PCB assemblies, such as multi-layer boards, HDI boards, or boards with very fine components, often require a special HS Code.

Multi-layer boards are considered more valuable and technically advanced, so they are treated differently from simple single-layer boards.

HDI boards are very small with high-density connections, which also affects their classification.

Using the correct HS Code for these high-end boards avoids delays, fines, and confusion at customs.

How to Correctly Classify PCB Assembly

Correct classification of your PCB assembly is very important. Using the wrong HS Code can cause delays, fines, or even rejected shipments. Let’s go through the steps clearly.

1. Determine Whether the PCB Assembly is a “Semi-Finished” or “Finished Product”

The first step is to check the stage of your PCB assembly:

Semi-finished PCB: This is a board that has some components but is not ready to be used in a final product. For example, a board with only a few chips soldered but missing connectors or other parts.

Finished PCB: This is a fully assembled board that is ready to be installed in a device or sold as a complete product.

Identifying the stage correctly is the foundation of choosing the right HS Code. Semi-finished and finished boards usually have different codes because customs treats them differently.

2. Choose the HS Code Based on Function, Layers, and Use

Next, consider what the board does, how it is built, and where it will be used:

Function: Does the board perform basic connections, or is it part of a complex device like a smartphone or medical equipment? High-function boards may have special codes.

Layers: Single-layer, double-layer, or multi-layer boards can fall under different classifications. Multi-layer boards are often more advanced and valuable.

Use: Some boards are meant for testing or research, while others are final components for electronics products. Their intended use can affect the HS Code.

Matching the code to these factors ensures the board is classified accurately.

3. Avoid Common Classification Mistakes

Many mistakes come from rushing or guessing the HS Code:

Using the code for a finished board on a semi-finished board, or vice versa

Ignoring the number of layers or the board’s function

Assuming all boards from the same manufacturer share the same code

These errors can lead to customs delays, fines, or extra paperwork. The best approach is to double-check the board’s stage, function, and construction before shipping, and if possible, confirm with your customs broker or the importing country.

Practical Tips to Avoid Customs Problems

Shipping PCB assemblies internationally can be tricky. Small mistakes can cause delays, fines, or even returned shipments. Here are some practical tips to help you avoid these problems.

1. Provide Complete Commercial Invoices and Technical Documents

Always include a full commercial invoice and clear technical documents with your shipment.

The invoice should list the product name, HS Code, quantity, value, and country of origin.

Technical documents, like datasheets or assembly drawings, help customs understand exactly what your PCB assembly is and how it works.

Providing complete and accurate paperwork speeds up clearance and reduces the chance of inspection or fines.

2. Communicate with Customs or Professional Brokers

Before shipping, it’s a good idea to talk to customs officers or a professional customs broker:

They can confirm that your HS Code is correct for the type of PCB assembly you are shipping.

A broker can also advise on any country-specific rules or potential issues.

Clear communication ensures your shipment goes smoothly and avoids surprises at the border.

3. Pay Attention to Special Rules in Different Countries

Different countries may have special import rules for electronic components:

Some countries charge higher tariffs on certain types of PCBs.

Some restrict imports of boards used in medical, or high-tech devices.

Knowing these rules in advance helps you plan correctly and avoid fines or shipment delays.

4. Handle Disputes or Issues Professionally

If there is a customs dispute or question about your HS Code:

Respond quickly and provide any additional documentation requested.

Keep clear records of invoices, technical sheets, and correspondence.

Work with your broker or customs consultant to resolve the issue efficiently.

Being prepared and organized reduces stress and ensures your shipment clears as quickly as possible.

Conclusion

Choosing the correct HS Code is the key to smooth international trade for PCB assemblies.

Planning ahead, providing complete documentation, and talking with experts can help you avoid customs problems and reduce risk.

Understanding HS Codes clearly also helps save money and make your shipments more efficient.

If you have more questions about PCBs or PCB assemblies, feel free to contact PCB MASTER, a professional supplier of PCB and PCBA solutions.

FAQs

1. Can the same HS Code be used for different types of PCB assemblies?

Not always. Even if two PCB assemblies look similar, their function, construction, and stage matter a lot. For example, a single-layer PCB with a few components for a simple device may have one HS Code, while a multi-layer HDI PCB for a smartphone has a completely different code. Using the wrong code can cause customs delays, fines, or extra duties. The best approach is to carefully check the board’s layers, components, and purpose, and if possible, confirm with your customs broker before shipping.

2. What happens if a PCB assembly is shipped without an HS Code?

Shipping without an HS Code is very risky. Customs officers won’t know how to classify your product, so they may hold the shipment for inspection, ask for extra paperwork, or even return it. In addition, they might charge higher duties or fines for missing information. To avoid this, always provide a clear HS Code, a detailed commercial invoice, and technical documents showing what the PCB assembly is, how many layers it has, and what it is used for. This makes the customs process faster and smoother.

3. How often do HS Codes change?

HS Codes are updated every 5 years by the World Customs Organization, but countries can add extra digits or make local adjustments more frequently. This means that an HS Code that worked last year might not be valid today in another country. Changes can affect duties, taxes, and clearance rules. Exporters need to check the latest HS Code lists before each shipment. Many companies subscribe to customs update services or work with brokers to stay up-to-date.

4. Can a customs broker help with PCB assembly HS Codes?

Yes, a customs broker is very helpful. Brokers know the rules and classifications for each country and can confirm the correct HS Code for your PCB assemblies. They also help with preparing invoices, technical documents, and certificates that customs may request. If there is a problem at the border, brokers can communicate with customs officers to resolve issues faster. Using a broker is especially useful for new exporters or complex boards like multi-layer or HDI PCBs.

5. Are there extra rules for high-tech or multi-layer PCB assemblies?

Yes, high-tech boards often face extra rules. Multi-layer or HDI boards are considered high-value and sensitive, so some countries require proof of function, technical datasheets, or import permits. They may also have higher duties or special handling requirements. For example, a board used in medical devices or telecommunications may need additional certification before it can enter a country. Preparing full documentation, accurate HS Codes, and consulting with brokers helps these shipments pass customs quickly without delays or fines.